Crucial Considerations for Selecting the Best Engine for Your Demands

In the realm of choosing the excellent engine to satisfy your requirements, a number of important factors need precise consideration to make sure optimal performance and effectiveness. From the nuanced balance between power and efficiency to the often-overlooked elements of upkeep and service demands, each element plays a crucial role in determining one of the most appropriate engine for your specific requirements. As the intricacy of engine technologies proceeds to develop, critical one of the most fitting choice demands a deep understanding of the interplay between different considerations. By discovering the elaborate web of variables that underpin this decision-making procedure, a clearer path emerges in the direction of picking an engine that not just meets but surpasses your assumptions.

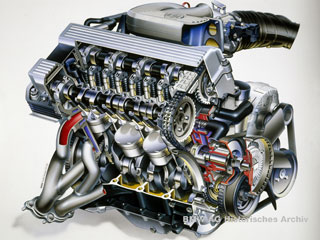

Power and Performance

When examining engines for optimum efficiency, it is important to focus on both power result and performance. Power outcome determines the capability of an engine to produce energy, which straight affects its efficiency. A high power outcome is vital for demanding tasks such as high-speed demands or durable applications. It makes sure that the engine can manage the work efficiently and effectively. Nevertheless, power alone is not sufficient; effectiveness plays a considerable function in figuring out the general performance of an engine. Efficiency describes just how well the engine converts fuel into useful power. A much more efficient engine will certainly provide better gas mileage, reduced discharges, and reduced operating prices. Striking the ideal balance in between power output and efficiency is key to picking an engine that meets your details requirements. When making this choice, it is necessary to think about factors such as the meant usage of the engine, environmental effect, and long-term expense implications. By meticulously examining both power and performance, you can choose an engine that supplies optimal efficiency and fulfills your demands effectively.

Gas Performance and Economy

Gas efficiency refers to the engine's capacity to transform gas right into energy with minimal waste, straight influencing operating expenses and environmental sustainability. Engines with higher fuel efficiency not just minimize fuel expenses yet additionally reduce carbon discharges, contributing to a greener operation.

Compatibility and Application

Considering the fuel performance and economic climate of an engine, the following vital element to address is its compatibility and application within specific operational contexts. Compatibility describes how well the engine incorporates with the overall system or devices it powers. It entails variables such as physical measurements, mounting alternatives, electric interfaces, and control systems. Ensuring compatibility is vital to avoid problems such as getting too hot, vibrations, or power inequalities (bmw 318ti).

Additionally, the application of the engine is just as important. Different engines are created for specific purposes, whether it be industrial machinery, aquatic vessels, automobiles, or power generators. Comprehending the intended application permits the selection of an engine that can deliver the necessary power outcome, torque, and functional qualities. A high-revving engine made for efficiency cars would not be suitable for heavy-duty building and construction tools that calls for high torque at reduced rates.

Upkeep and Service Demands

Upkeep and solution demands play an important duty in ensuring the durability and ideal efficiency of an engine. Normal maintenance is vital to prevent break downs, prolong the life-span of the engine, and keep its efficiency. When choosing an engine, it is essential to think about the supplier's suggested upkeep timetable and the schedule of solution facilities or certified technicians.

Factors such as the frequency of oil modifications, filter replacements, and general assessments can considerably affect the engine's efficiency. Some engines may need even more regular servicing based upon their layout and use, while others might have longer intervals between maintenance checks. It is crucial to stick to these solution demands to prevent expensive repair work and unexpected downtime.

Expense and Budget Factors To Consider

Budget plan constraints often find this play a significant duty in the decision-making process when picking an engine for a specific application. When taking into consideration the expense and budget plan effects of selecting an engine, it is vital to examine not only the preliminary acquisition cost yet additionally the long-lasting expenses connected with upkeep, fuel intake, and potential upgrades or repair services. It is essential to strike an equilibrium between the ahead of time cost of the engine and its general lifecycle prices to ensure that the picked engine continues to be economically lasting throughout its operational life expectancy.

Variables such as gas effectiveness, sturdiness, and dependability can straight affect the total price of ownership of an engine. While an extra costly engine might have greater upfront prices, it might potentially result in reduced maintenance and gas expenses over time, hence providing far better value in the long run.

Verdict

Fuel performance refers to the engine's ability to convert gas right into power with minimal waste, directly influencing operating prices and environmental sustainability.Variables affecting fuel effectiveness consist of engine layout, combustion efficiency, and general efficiency optimization. In addition, picking the appropriate fuel type and quality as advised by the engine manufacturer can even more improve effectiveness and lengthen engine lifespan.

Engines with good service functions and conveniently offered components can lower upkeep costs and minimize the time the engine is out of procedure - bmw visite site 318ti. It is critical to strike a balance between the upfront cost of the engine and its overall lifecycle costs to guarantee that resource the selected engine stays economically lasting throughout its functional life-span